INNOVATE. CUSTOMISE. AUTOMATE.

Your Medtech Solutions Partner.

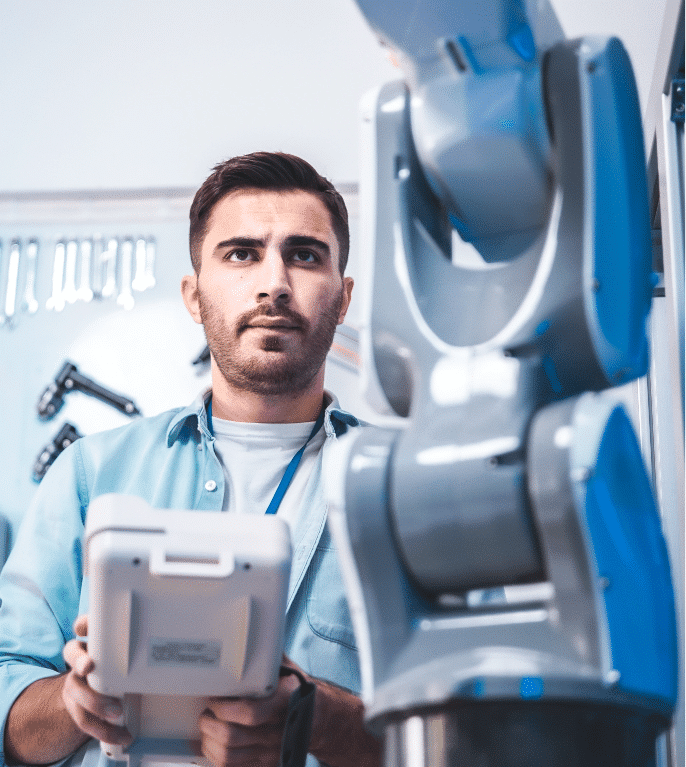

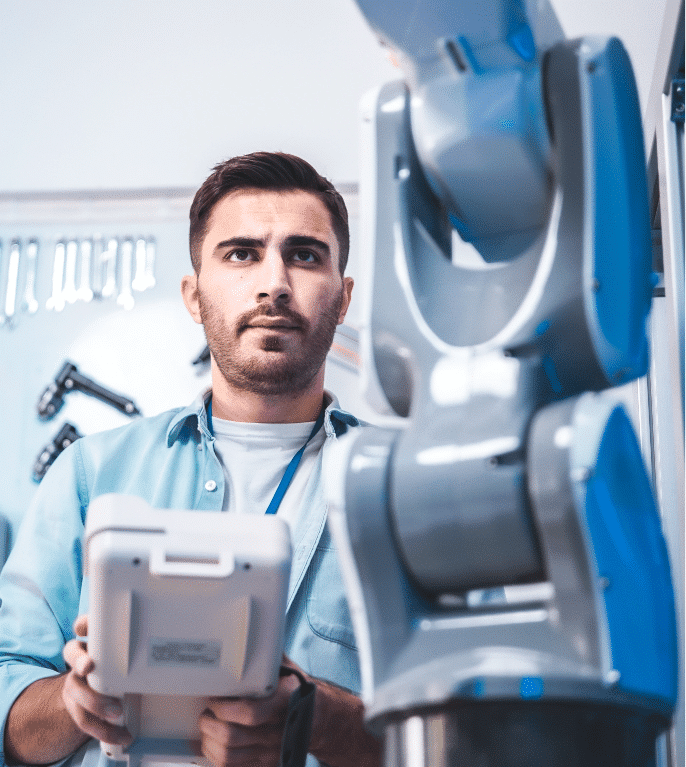

We are a passionate community of innovators and engineers who push the boundaries of automation and manufacturing on behalf of our customers.

We are a passionate community of innovators and engineers who push the boundaries of automation and manufacturing on behalf of our customers.

Products assembled

Fixtures manufactured

Machine builds

As specialised machine builders every new automation project drives us to challenge the boundaries of manufacturing. Innovation and creative thinking lie at the heart of everything we do which is why we have developed a reputation for delivering successful solutions to the world’s most trusted medical device manufacturers.

Offering a full set of in-house expertise in R&D, manufacturing, assembly, automation and installation, we collaborate closely with our clients in the MedTech industry to find the best, most advanced and tailored solutions.

From product design to production processes, we seek to minimise our environmental impact and leave a positive legacy for future generations. Sustainability is not just a goal, but a guiding principle that informs every aspect of our work at DesignPro Automation.

People you want to work with

As bespoke machine builders, we stay at the forefront of the latest technology so we can deliver smart, innovative designs to improve your output.

We understand that every project is unique. We collaborate closely with your team and adapt to suit your specific needs.

We build strong working relationships through our open approach and detailed project documentation.

Pushing boundaries of the manufacturing industry to deliver the best possible solutions.

Embracing new technologies, partnerships and processes so that we can offer competitive, cutting-edge solutions.

We operate in a collaborative culture utlising our teams in depth knowledge to overcome challenges on complex projects.

We take great pride in our work, our solutions are finished to the highest possible ISO9001:2015 standards.

The strength of our customer support lies in our in-depth knowledge of the mechanical and electrical workings of every machine we build.

Explore Our Work In More Detail

Get in touch with one of our automation experts.